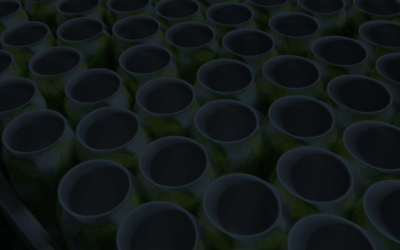

Accurate impact force measurement in bottling and packaging is crucial for grasping the root cause of shocks, especially those quantified in Inches Per Second (IPS). It equips fillers with the knowledge to improve line efficiency and minimize container...