Measure pressure and scuff to inform maintenance decisions, reduce aesthetic damage to cans and maximize filling cycles from returnable glass.

Pressure, friction, and scuffing on the line causes wear marks on containers and reduces the number of filling cycles of returnable glass.

Damage from squeeze load is impossible to measure without PressureQC™+ Scuff, the industry’s only scuff measurement. Actionable data can inform maintenance decisions such as lubrication and conveyor adjustments. Container damage from friction, particularly in aluminum cans, can also be alleviated.

How the process works:

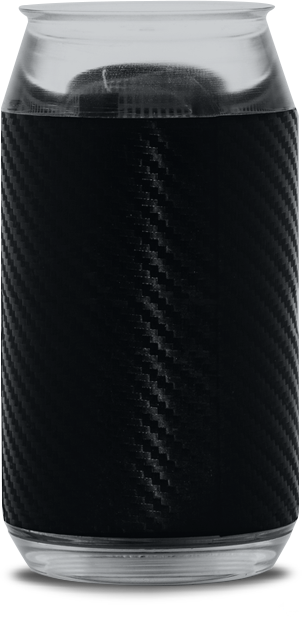

Outfitted with pressure sensitive film, PressureQC™ + Scuff smart sensor replicas are placed on the line to measure scuff for glass and canning industries. Location beacons identify where to take immediate corrective actions to minimize rejects and extend container life..

Scuff

Extend returnable bottle life by reducing scuff wth the industry’s only measure of a container’s pressure, friction and spin velocity.

Pressure

Reduce scuffing and abrasion damage by controlling external force measured in pounds-force or Newtons.

Spin & Tilt

Control label and pressure damage by reducing degrees per second of container tilt and spin.

Features & Benefits

Extend the life of returnable glass up to 4 years.

Significantly reduce scuffing and aesthetic damage.

Identify areas of potential glass breakage and damage to cans.

Determine maintenance and capital investment priorities.

Improve the efficiency of line changeovers.

Relieve areas of high pressure causing premature equipment wear.

Impact & IPS Measurement [ More+]

The packaging industry’s only measurement and visualization of scuffing.

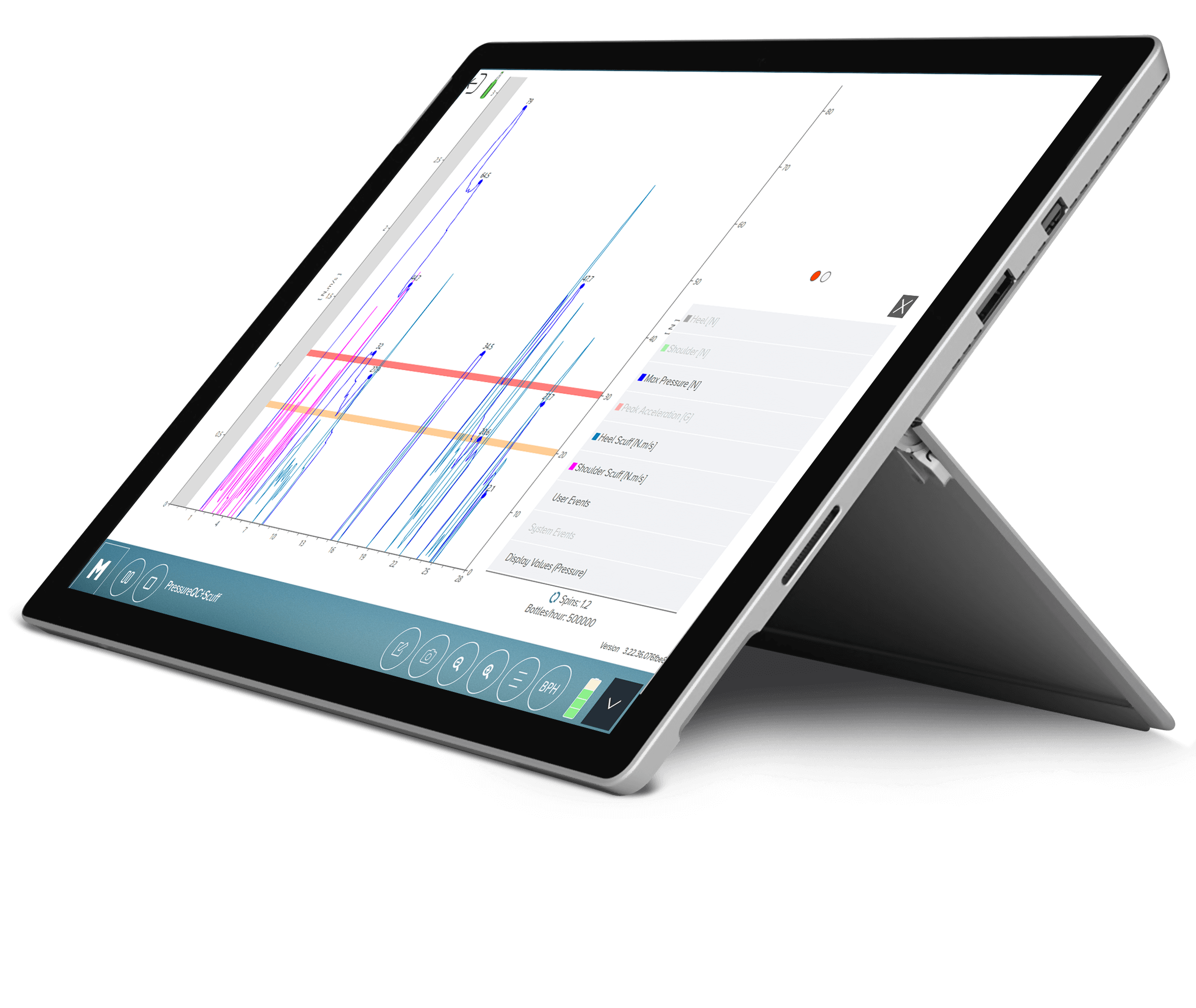

Line Intelligence Visualization

Executive dashboard data analysis for quick insights and trending through modern data visualization.

Adjustable Height Scuff Sensor

Optional multi-height sensor lowers cost of ownership, enabling scuff measurement for multiple containers within 5mm diameter.

Custom Acrylics

Heat and water resistant acrylic replicas are based on your containers’ CAD drawings for absolute accuracy.

Video & Location Tracking

Wireless Bluetooth beacons combined with integrated video pinpoints and visualizes locations of high pressure and friction.

Transportation Mode [ More+]

Deploy in a case or pallet during shipping for a dock-to-shelf account of your product’s transportation journey.

Technical Specifications

Data Recording

Sampling Rate: Up to 100,000 samples/second.

Battery

Type: Rechargeable Li-Ion

Charge: 8 hours continuous use

Pressure Detection

Multiple pressure films with independent calibration and custom measurement range

Bluetooth

Range: 300 ft.

Other: Dual-mode Bluetooth 4.0

Configurable App

Customized thresholds quickly detect areas where scuff measurements exceed recommended levels.

Pre-Loaded Tablet

The Masitek app ships pre-loaded on a Windows-based tablet for quick set-up and real-time calibration.

Web-based Dashboard

Compare data runs and generate reports from anywhere via an easy to use web interface.

Insight, trends & detailed analysis.

Monitor trends such as line degradation or improvement over time.

The Masitek solution dashboard delivers actionable information about friction, squeeze load and pressure on the line to improve and enhance your routines.